Parallel Marine Generators

Everything you need to know about parallel generators and the options we offer.

What is generator set parallel operation and what advantage does it have?

The configuration for parallel generators consists of synchronizing two or more generator sets that are coupled together with the same frequency and voltage. They then operate jointly, supplying power to the same network. In this way, energy can be generated in large quantities, which could never be supplied by a single generator set with the same specifications.

The parallel operation system always keeps one main generator set switched on and connected to the network. The main generator set may be a different unit from time to time. By alternating the operation of the generator sets in this way, their working hours are distributed across the generator sets, staggering their maintenance.

As soon as the demand for electricity increases beyond a pre-set limit, the system starts up the next generator set and automatically connects it to the network. The load is then distributed equally among all the generator sets that are connected.

When the load falls below the pre-set limit, the appropriate generator sets are automatically switched off and stopped.

For maintenance purposes, it is possible to keep providing the power supply even if one of the generator sets is out of use. The system detects this and will disregard this equipment.

Some of the most important advantages of using parallel operation systems are:

- The possibility of supplying quantities of energy in a way that is more efficient and consumes less fuel. This is due to the fact that parallel operation systems are better able to adapt to the current energy needs. They are able use one unit when there is low consumption, and connect or disconnect more units depending on the level of network load..

- The safety provided by a system that allows maintenance tasks to be carried out on one of the units while the other units continue to operate, maintaining the power supply at all times, under any circumstances. This power supply would be guaranteed if the main unit fails, or is undergoing maintenance.

- The reliability provided by the fact that more than one generator set is operating at the same time. This avoids failures, and guarantees that there is a power supply at all times.

- The reduction in maintenance required for each generator set, as the operating hours for each unit are decreased.

Why is the parallel operation with Solé Diesel generator sets the best option?

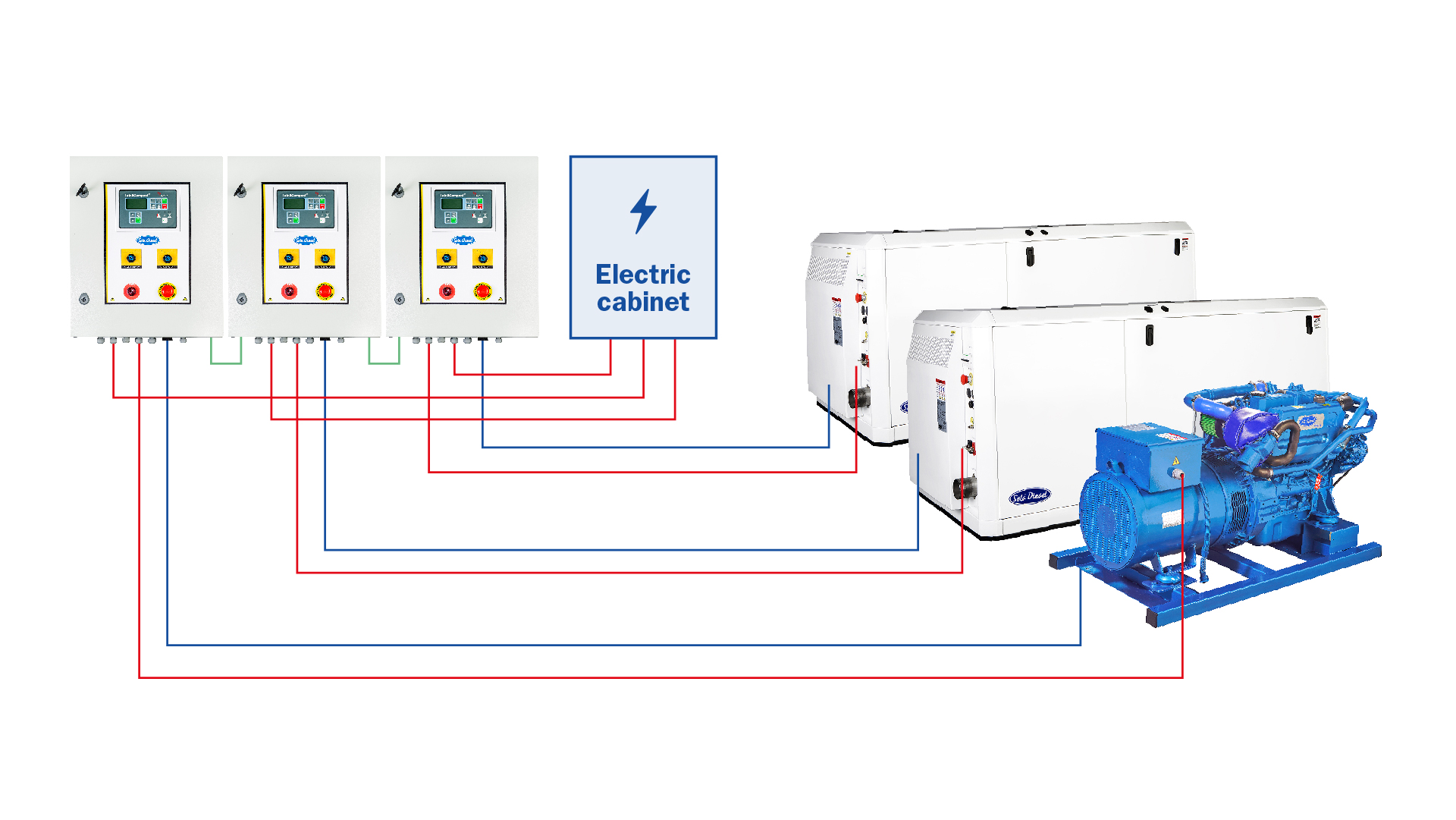

At Solé Diesel, we want to make things convenient for our customers, facilitating the start-up of this complex equipment. As a result, we have set ourselves apart from the other solutions that are on the market, by offering a Plug&Play system. This consists of a generator set that is ready for parallel operation, as well as an electrical cabinet that includes a power switching system and a controller which are fully configured for this application.

Technological advances have made it possible for these operations to be carried out automatically, using a specific controller for the parallel operation of generator sets. Each generator set has a controller that regulates the frequency and voltage. These parameters must be maintained in the same proportion in all the generators to ensure optimum performance. In addition, these controllers succeed in delivering a significant reduction in time, complications and costs incurred during start-up.

What options do we offer?

At Solé Diesel, we offer two supply levels for the parallel operation generator set system. The combination of both levels provides an easy to install experience that is 100 % safe and effective.

Option 1: Generator set prepared for parallel operation is ideal for replacing one or more generator sets that are integrated within an existing parallel operation system.

It includes the Generator set, the electronic controller and the Engine Control Unit ECU. The scope of this supply would not include any control panels, synchronizing or switching equipment.

Equipment Option 1:

Generator Set prepared for parallel operation:

- Generator Set that is ready for parallel operation. The panel and the control and power cabinet are not included.

- ECU

- Electronic actuator

- Control wiring.

Option 2. Generator Set prepared for parallel operation (Option 1) + Parallel Operation Control and Power Kit.

This is our Full Equip option, which is highly recommended for boats where a parallel operation system is being installed for the first time.

As it is Plug&Play, there is no need to carry out any complex configuration or installation of the parallel operation system. Simply connect the Cabinet Kit to the generator set, and to the network.

This is the option that is recommended by Solé Diesel, as it saves the user money on engineering and installation costs.

Equipment Option 2:

Generator Set prepared for Parallel operation (Option 1) + Parallel Operation Control and Power Kit.

- Generator Set that is ready for parallel operation. The panel and the control and power cabinet are not included.

- ECU.

- Electronic controller.

- Control wiring.

- InteliGen2000 Control Panel.

- Control and Power Cabinet For parallel operation.

- Communication wiring.

- Control wiring.

- Load break switch.

- Amperometric transformers.

- Electrical protections.

The cabinet kit that contains the Parallel Operation Control and Power Kit consists of an electrical cabinet which has a load break switch in it that connects the generator set to the network.

Additionally, it contains an Inteligen2000 controller that communicates with the parallel operation system and allows the generator set to be started and stopped manually or automatically. It also provides different measuring and control equipment to ensure that the parallel operation system functions efficiently and correctly.

Finally, it has all the necessary protections to keep both people and equipment safe.